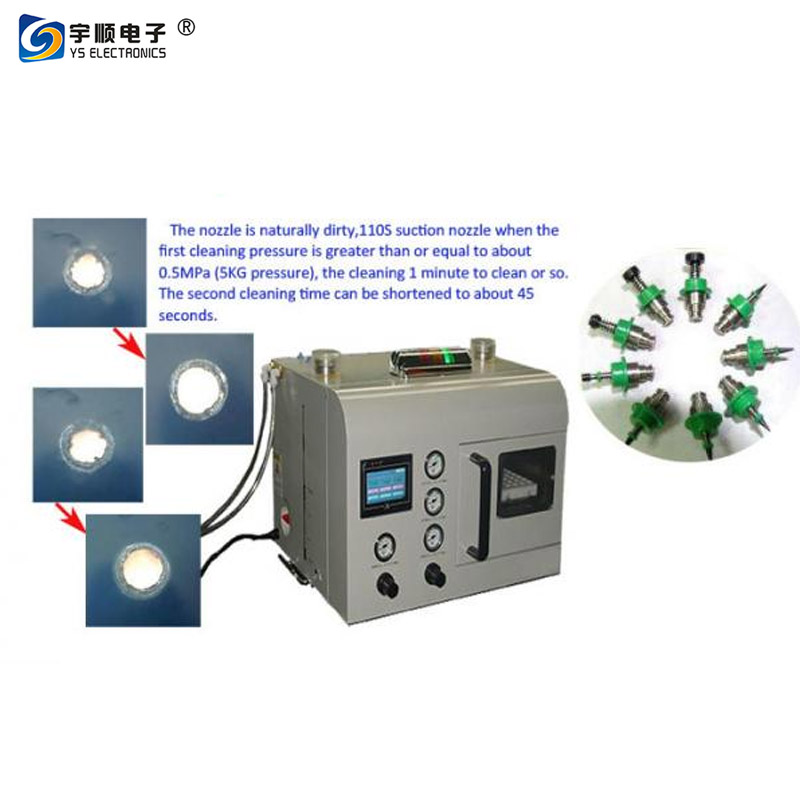

Nozzle Cleaning Machine, Automation/Cleaning Nozzle Equipment, Introduction and use of the machine:

Composition Introduction:

1. mechanical :All the key parts of the whole use of imported 304 stainless steel, special parts of the use of imported 316 stainless steel to

The warranty machine will not rust due to the use of water, thus affecting the equipment life and other security risks;

2. pneumatic : The use of all imports of SMC pneumatic components, to better ensure a stable and efficient work efficiency;

3. control : The machine adopts high quality touch screen man - machine interface, PLC control;

2. Precautions:

1.Do not open the water cover in the ventilation cleaning or drying. If there is a high pressure in the storage tank,Mouth jet out.

2.Please use distilled water or industrial deionized water, do not use mineral water or tap water, such water contains minerals and bleach, the nozzle will cause damage and damage;

3. After each cleaning is completed using air guns to dry the residue in the studio;

4.After each time you place the nozzle, make sure that the nozzle is fully seated and the nozzle is fit with the fixture.

5. Place the tool into the studio when the carousel should be careful not to hit the telescopic cylinder nozzle, If not very strong collision does not affect the nozzle and the concentricity of the device. Sprinkler and appliance concentricity The factory is positioned by positioning the sensor. Such as strong collision lead to concentricity are not allowed to contact with the after-sales maintenance staff in a timely manner;

6. Regularly replace the equipment intake filter every year, The general replacement of the filter time for a year, depending on the factory gas source clean to determine, such as filter filter yellow or black need to immediately replace.

Nozzle Cleaning Machine, Automation/Cleaning Nozzle Equipment Specifications:

Air pressure | Air pressure | Compressed air |

Intake pressure setting | 0.5~0.55MPa | |

Injection pressure setting | 0.35~0.38MPa | |

Nozzle injection pressure | ≤0.4MPa | |

Consumption of gas | ≤260Nl/min | |

tube | Intake trachea | ¢12 tubes |

Drainage tank | ¢8tubes | |

Cleaning fluid | Cleaning fluid | Industrial deionized water |

Consumes liquid | ≤300cc/h(5cc/min) | |

Storage tank capacity | 1200cc | |

power supply | power supply | AC220~240V |

plug | 3-Pin | |

Consume electricity | ≤0.1Kw | |

surroundings | Working temperature | -5~ (But not frozen) |

Liquid temperature | 0~ (But not frozen) | |

Working environment humidity | 10~60%RH | |

Equipment placed in the environment humidity | 10~60%RH | |

dust | 0.1mg/m³(There is no conductive dust) | |

Corrosive gases | Not allowed | |

other | Dimensions | 655(L) x 560(W) x 475(H) |

weight | ~(Contains cleaning solution2000cc) |

Nozzle Cleaning Machine, Automation/Cleaning Nozzle Equipment Features:

A one-time into the 36 nozzle, please wash large;

Completely solve the dirt is difficult to clean the dirt impurities;

Though the smaller nozzle aperture but cleaning is clean;

Cleaning more thoroughly directly extend the life of the nozzle;

No damage to the surface of the nozzle coating, reflective plate;

Use environmentally friendly deionized water or distilled water to clean;

Automatic continuous cleaning, automatic drying;

Operation is more simple and convenient;

Increased intelligent water storage check function;

Applicable to all kinds of placement machine.