3. The system automatically corrects according to the installation position of the product to ensure high-precision cutting requirements.

4. Installed with a static eliminator to remove electricity, dust and air nozzles continue to work, to eliminate static electricity generated when high-speed spindle cutting, to avoid damage caused by static electricity, to avoid the accumulation of dust due to static electricity.

6, The cleaner is equipped with a dust collection box (Maintenance can be arranged according to capacity cutting requirements or dust collection time).

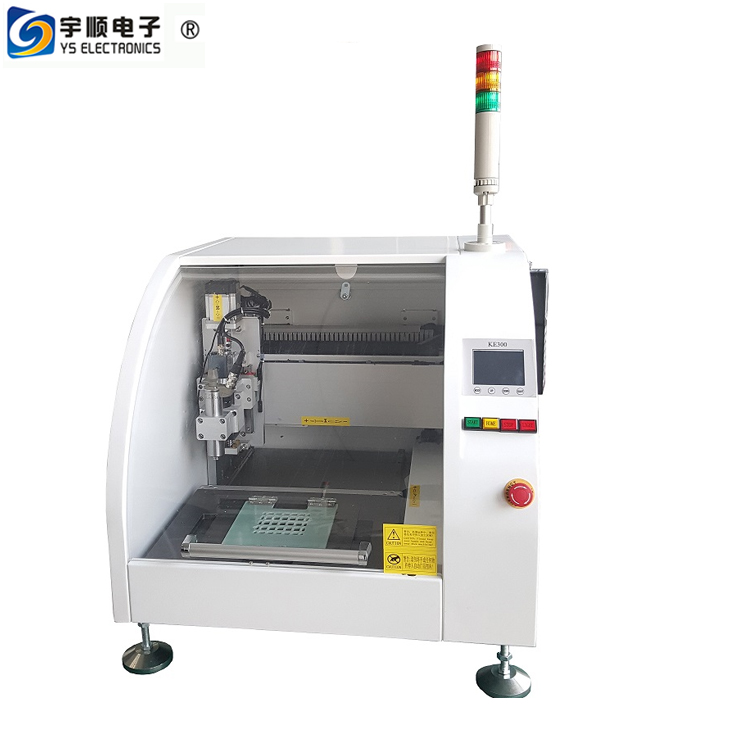

Suitable for split stamp hole PCB board and irregular joint PCB board

Technical Parameters:

Hardware Demand |

YS-300 |

L623*W737*H587mm |

220V/50HZ |

3.6KW |

About 300KG |

Inside / L650*W500*H550mm |

2.2KW/220V |

260mm*260mm |

0-100mm/s |

X, Y axis 0-1000mm/s (min), Z axis 0-750mm/s (min), servo motor drive |

±0.01mm |

X:0-260mm,Y:0-260mm,Z:0-80mm |

0.5-5mm |

0.8-3.0mm |

±0.01mm |

Linear, Circular, U-curve, Arc, L-curve |

Manual, tools needed |

The number of milling cutters (0-5 section) |

none |

controlled by Program |

1pc |

60000rpm |

Air cooling mode |

collect dust downside |

220V ,50HZ |

0.4Mpa |

Safety door and door lock sensor |

offline, load and unload PCBA by hand |

Self-diagnosis,display failure information in real time, query IO state visually, easy for troubleshooting |

IPC, Windows 7 |

USB |

Password protection,the operator enter corresponding interface according to authority to protect important parameters.) |

Visual interface, the cutting point capacity for a single program should be over 400, dynamic simulation of cutting schedule |

Yes |

universal fixture |

≤78 dB(measured in 1M’s distance ) |

1 years |

(Offer service of operation, programming, hardware caring and maintenance training; free upgrade of application. ) |