Applicable working conditions

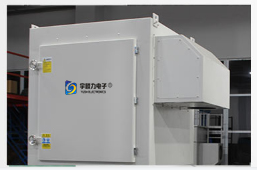

Plasma laser cutting dust collector,YSL-1100B variable frequency constant pressure large air volume dust collector, is equipped with centrifugal fan, which has large air volume and low noise. The machine is equipped with Siemens inverter control system, which can automatically adjust the power of the motor, realize the variable speed operation of the motor, maintain a constant air volume and air pressure, and achieve the purpose of saving electricity. Plasma laser cutting dust collector programmable controller controls pulse cleaning method, 15 filters 100M² filter area, built-in air duct and other designs to ensure that the machine can be used stably for a long time in an environment with a large amount of dust without being blocked. The constant pressure control of the plasma laser cutting dust collector can monitor the negative pressure during use and remind to replace the filter; it is small in shape and low in noise, and is often used in laser cutting machines above 2.5*8 meters, plasma laser cutting machines, and robot welding workstations for equipment matching dust removal ;

Product Description

1. The centrifugal fan of the plasma laser cutting dust collector has large air volume, low noise and stable performance; the cabinet modular design power, air volume, suction force, suction port and pipe diameter can be customized according to customer needs.

2. The Siemens inverter of the plasma laser cutting dust collector can automatically adjust the power of the motor, realize the variable speed operation of the motor, maintain a constant air volume and air pressure, and achieve the purpose of saving electricity; it can control the starting current of the motor, fully reduce the starting current, Reduce the maintenance cost of the motor.

3. Standard remote/local switch function, you can choose a local switch or a linkage switch with the equipment according to the working conditions.

4. The plasma laser cutting dust collector is equipped with a differential pressure gauge to measure the pressure when the machine is running. When the negative pressure exceeds the set value, it reminds to replace the filter.

5. External 60L pull-out dust collector.

6. 15 filters, the filter area is increased to 100M² to prolong the service life of the filter

7. The programmable pulse controller of the plasma laser cutting dust collector controls the pulse cleaning method, and the interval time of the automatic pulse cleaning filter can be set.

8. The installation method of the air inlet hose on the plasma laser cutting dust collector can avoid the wind loss caused by the narrow area.

9. The internal filtering wind speed reduction design of the plasma laser cutting dust collector machine can form dust reduction inside the machine after dust inhalation, reducing the dust adhesion to the filter.

10. The plasma laser cutting dust collector is small and has low noise and can be placed indoors or outdoors.

Frequency conversion constant voltage control system Differential pressure gauge

heavy duty door lock Separate dust bucket

Duct chain interface Cartridge type high efficiency filter

| Technical Specifications | Unit | YSL-1100B |

| power | KW | 11 |

| Voltage | 380V | |

| capacity | L | 60 |

| Suction diameter | MM | 500 |

| Filtration accuracy | μm | 0.1~0.3 |

| number of filters | EA | 15 |

| Filter size (diameter*height) | mm | 200*1100 |

| total filter area | M² | 110 |

| air flow volume | M³/H | 10000~13000 |

| noise | DB | 74 |

| vacuum suction | Kpa | -2.0~-3.0 |

| Power cord length | M | 10 |

| weight | KG | -- |

| Air pressure | 0.4Mpa≤work value≤0.6Mpa | |

| Size (L*W*H) | MM | 1400*1300*2500 |

Plasma laser cutting dust collector is mainly used for laser cutting machines above 2.5 meters, the collection and treatment of floating and suspended dust with a large amount of dust, and the small central dust collection system for multi-station operations; suitable for grinding, cutting, stirring, spraying Sand, ceramics, paper, steel, food, plastic, wood processing and other industries;