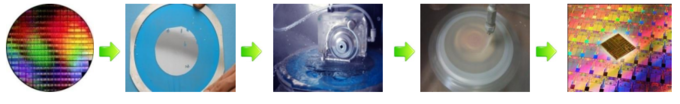

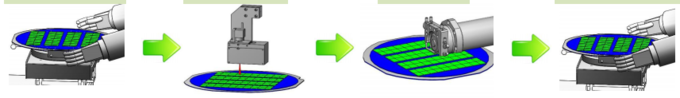

2.The cutting position is automatically calibrated.

3.Press the start button to automatically complete the dicing process of material.

4.Operator take the material manually being cut from the work platform.

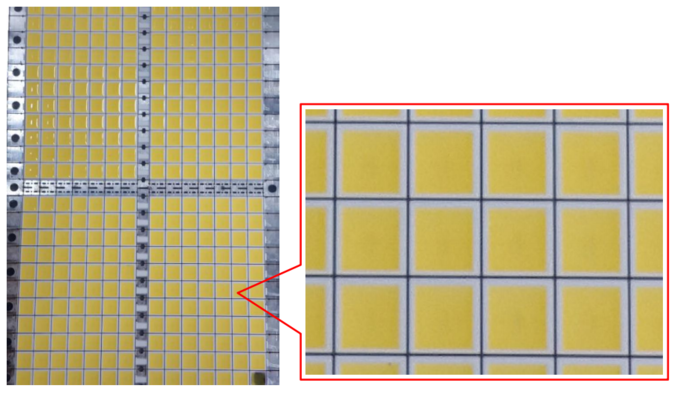

Applications

3.Please control the temperature of the cutting water at 22 ~ 27 ℃(variation ranges in ±1℃ ), the cooling water at 20 ~ 25 DEG C (variation ranges within plus or ±1℃).

4.Please avoid the equipment to be impacted and any vibration of the outside world. In addition, please do not install the equipment near the device like blower and vent that produces a high temperature and a device that generates oil mist.

5.Please avoid the equipment to be impacted and any vibration of the outside world. In addition, please do not install the equipment near the device like blower and vent that produces a high temperature and a device that generates oil mist.

6.Please follow the product manual we provided for operation strictly.

| System compositionproject | Unit | Specification | |

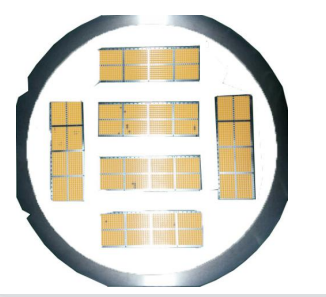

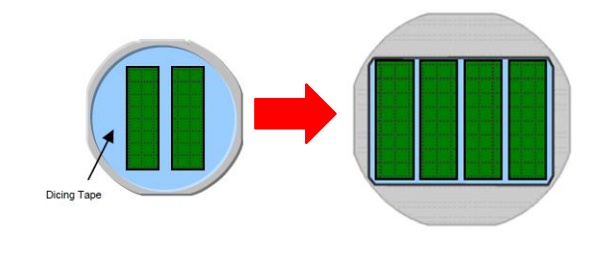

| Dimensions of processing | mm | Φ300 | |

| Dimensions of working platform | mm | Φ350 | |

| X-axis | Working stroke | mm | 340 |

| Cutting speed | mm/sec | 0.05 ~ 400 | |

| Resolution | mm | 0.0001 | |

| Y-axis | Working stroke | mm | 310 |

| Resolution | mm | 0.0001 | |

| Repeat positioning accuracy | mm | 0.001 / 310 | |

| Z-axis | Working stroke | mm | 60 (2 Inch blade) |

| Resolution | mm | 0.0001 | |

| Θ-axis | Angle of rotation | Deg | 360 |

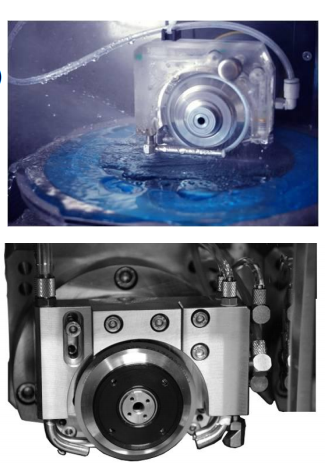

| Spindle | Power | KW | 2.4 |

| Speed | Rpm | 5000 ~ 60000 | |

| Machine’s specifications | Power supply | V | 3P 220 (50 ~ 60 Hz) |

| Machine power | KW | 4 | |

| Power air pressure | MPa | 0.5 ~ 0.6 | |

| Air consumption | L/min | 200 | |

| Cutting water consumption | L/min | 4 | |

| Cooling water consumption | L/min | 1.5 | |

| Physical dimension | mm | 1040×1080×1750 | |

| Machine net weight | KG | 850 | |