Welcome to the official website YUSH Electronic Technology Co.,Ltd

| SE series reflow oven main specifications (Daul Rails) | |||||||||

| Model No | YSL-708AHSE Daul Rails | YSL-708HSE Daul Rails | YSL-708NHSE Daul Rails | YSL-710AHSE Daul Rails | YSL-710HSE Daul Rails | YSL-710NHSE Daul Rails | YSL-712AHSE Daul Rails | YSL-712HSE Daul Rails | YSL-712NHSE Daul Rails |

| Heating System | |||||||||

| Heating Zone | 8 heating zones, 16 heating modules | 10 heating zones, 20 heating modules | 12 heating zones, 24 heating modules | ||||||

| Heating Length | 2950mm | 3670mm | 4350mm | ||||||

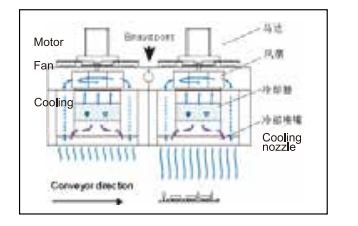

| Cooling Type | Double cooling:enforced air cooling/water cooling(Optional:three cooling zones) | ||||||||

| Outlet Exhaust Diameter valume | 2-145,Exhaust demand 15m³/min*2 | ||||||||

| Conveyor System | |||||||||

| Product width | Min50mm-Max270mm(simultaneously)/(Optional:Simultaneous overboard max300mm) | ||||||||

| Min50mm-Max500mm(single track)/(Optional: single track over board max550mm) | |||||||||

| Conveying Direction | L→R,R→L | ||||||||

| Inlet Height | 900±20mm | ||||||||

| Fixed Rail Side | Front and Rear End Rails Fixed,2 Central Rail adjustable | ||||||||

| Conveyor Type | Chain+mesh belt synchronous transmission | ||||||||

| Cmponent Height | Clearance based on the rail:above 30mm,below 20mm | ||||||||

| Conveying speed | 300mm-1500mm/min(Option:Double Speed) | ||||||||

| Control System | |||||||||

| Power Supply | AC3 5W 380V 50/60Hz | ||||||||

| Total Power | 70KW | 89KW | 108KW | ||||||

| Start Up Power | 35KW | 40KW | 42KW | ||||||

| Running Power | 10KW | 11.5KW | 13KW | ||||||

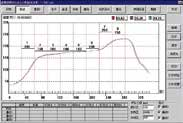

| Temperature Range | Room temperature to 320℃ | ||||||||

| Control type | PC+PLC Control system | ||||||||

| Rail Width Adjusting Mode | Electric+Manual | ||||||||

| Temp Control accuracy | ±1℃ | ||||||||

| PCB Temp Deviation | ±2℃ | ||||||||

| Data Storage | Process Data and status stotage | ||||||||

| Power Outage Protection | Equipped with UPS | ||||||||

| Operation interface | Windows Chinese simplified,English online free switching | ||||||||

| General | |||||||||

| Dimension(L*W*H) | 5055*1610*1515mm | 5775*1610*1515mm | 6495*1610*1515mm | ||||||

| Weight | 2500-2700KG | 2900-3100KG | 3300-3500KG | ||||||

| Color | Bright wrinkled white | ||||||||

Manual+electric width adjustment structure design, equipped with emergency manual transmission structure in case of preventing PCB burned when power off.

Conveyor system:stable and reliable anti-deformation structure design.