Welcome to the official website YUSH Electronic Technology Co.,Ltd

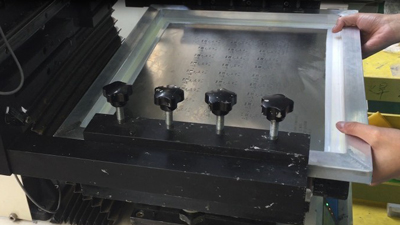

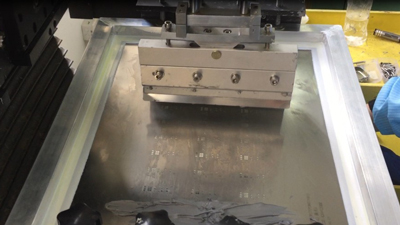

Accuracy: | ±0.05mm | PCB Size: | 300 X 350 Mm |

Platform Size: | 700 X 400 Mm | Stencil Size(mm): | 370*470,550*650 |

PCB Thickness: | 0.2 - 6 Mm | Stencil Positioning: | Manual |

| odel | P3 | P6 | P12 |

| Accuracy | +/- 0.05mm | +/- 0.05mm | +/- 0.05mm |

| PCB Size | 300 x 350 mm | 600 x 350 mm | 1200 x 350 mm |

| Platform size | 300 x 350 mm | 700 x 400 mm | 1350 x 400 mm |

| Stencil Size(mm) | 370*470,550*650 | 370*470,550*650 | 370*470,550*650,1500*650 |

| PCB Thickness | 0.2 - 6 mm | 0.2 - 6 mm | 0.2 - 6 mm |

| Stencil Positioning | Manual | Manual | Manual |

| Cycle Time | < 10 Sec. | < 10 Sec. | < 12 Sec. |

| Power Consumption | 200 W | 200 W | 200 W |

| Power Supply | 1 -PH, 220VAC 50/60HZ | 1 -PH, 220VAC 50/60HZ | 1 -PH, 220VAC 50/60HZ |

| Air Pressure | 4.5-6 kg/cm | 4.5-6 kg/cm | 4.5-6 kg/cm |

| Squeegee Speed | 0-1500mm/sec | 0-1500mm/sec | 0-1500mm/sec |

| Dimension | 850x750x1650 mm | 1050x750x1650 mm | 1660x750x1650 mm |

| Weight | 280 Kg | 300 Kg | 356 Kg |

| Squeegee Length | 250mm | 250mm | 250mm |

| Platform Height | 950mm | 950mm | 950mm |

| Option: Special size can be customized | |||

| odel | L8 | L10 |

| Dimension (L*W*H)mm | 5000x1250x1490 | 5800x1250x1490 |

| Weight | Approx. 1600KG | Approx. 1800KG |

| Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 |

| Length Of Heating Zones | 3121mm | 3891mm |

| Rail Width Adjustment | M(option:A) | |

| Exhaust Volume | 10M3/minx2 Exhausts | |

| Control System | PLC+Computer | |

| Temperature Control Method | PID + SSR | |

| Model | 622 | 733 | ||

| Dimension (L*W*H)mm | 5040x1450x1450 | 5800x1450x1450 | ||

| Machine Weight | Approx. 2200KG | Approx. 2400KG | ||

| Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 | ||

| Length Of Heating Zones | 3030mm | 3730mm | ||

| Number of Cooling Zones | 2 | 3 | ||

| Control System | PLC+Computer | PLC+Computer | ||

| Transmission Agent | Chain + Mesh | Chain + Mesh | ||

| Max.Width Of PCB | 460mm | 460mm | ||

| Power For Warm Up | 45kw | 55kw | ||

| Power Consumption | 8kw | 10kw | ||

| Conveyor Height | 900+/-20mm | 900+/-20mm | ||

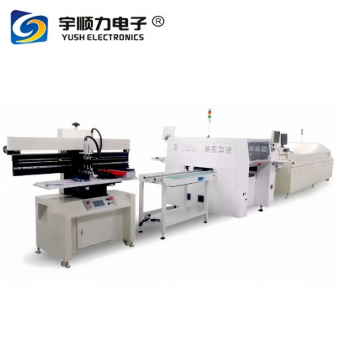

Simple process flow:

Loader → Printing Machine → Pick-and-Place Machine → Reflow Oven → Inspection Machine → Repair

Complex process flow:

Loader → Laser Marking Machine → Cleaning Machine → Printing Machine → Solder Paste Detection Machine → Pick-and-Place Machine → Reflow Oven → Optical