Solve the difficulties in DIP welding

1.Solve the flexible production of multiple varieties and small batches (flexible and convenient)

2.Quick online welding, no fixtures required (direct welding can be done with a safe distance)

3.Extremely low equipment purchase cost (low initial investment cost)

4.Extremely low usage and maintenance costs (saving tin slag, flux, electricity and consumables)

5.The tin penetration rate is 100% and the welding yield rate is over 98%

6.Extremely low floor area (about 1 square meter)

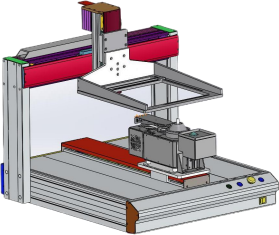

Selective wave soldering working mode

During offline selective welding,the welding nozzle is fixed.

The PCB board is set according to the program.

Move in the X,Y, and Z axes to achieve the soldering of PCB solder joints.

Specification items

Specification items | YS-E320 |

Applicable PCB board size | L*W : 50×50~450×400 mm |

Applicable PCB board thickness | Substrate thickness:0.8~3 mm / Pin length:Within 3mm |

Component height | Less than 100mm above the substrate / Less than 50mm below the substrate |

Substrate shape and conditions | 1.Substrate placement edge:The edge of the substrate process is more than 3mm 2The weight including components is less than 5 kilograms 3.The bending of the substrate: less than 0.5mm |

Tin furnace | Tin furnace material/capacity:Stainless steel material / 10KG tin tank capacity:Power:4*500W 2 KW |

N2 Requirements | Nitrogen purity:99.999% Pressure/Consumption:0.5MPa / 20/min~30/min / 1.2-1.5Cube H |

Flux nozzle | Precision fluid nozzle |

Flux capacity | 2 L (Manual liquid addition) |

Gas source | 0.5-0.7Mpa |

Nozzle inner diameter | φ 3mm~φ 20mm Customizable size |

Peak height | Automatic alignment/height measurement |

System control | PC+PLC(windows+Huichuan) |

Programming software | Support programming for drawing lines on pictures(Convenient and fast) |

Power supply/power | Single-phase 220V±10% Starting power:2.5KW |

Weight | 70KG (Containing solder10KG) |

External dimensions | L*W*H 730×800×840 mm |