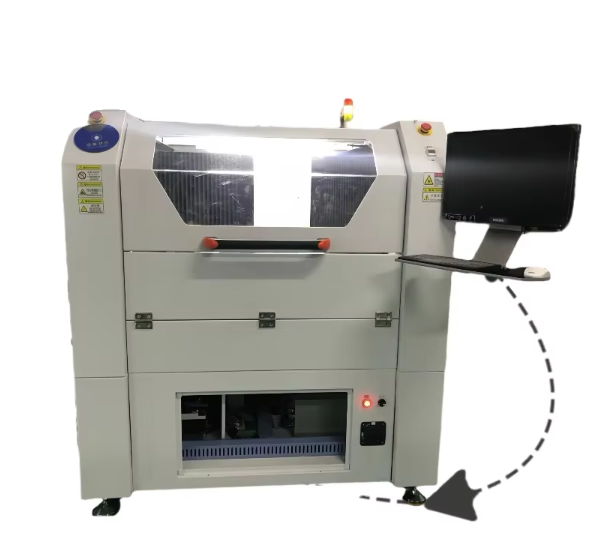

SMT Laser template cutting machine

YS-GW100W is Yush's new generation of SMT laser template cutting machine.There is a significant improvement in both performance and user-friendly operation design which compared with the previous models.According to market demand The overall performance of the machine has been upgraded to a new level.While improving the cutting speed,also guarantees its excellent cutting quality.Performance is comparable to imported equipment, and the cost performance is much higher than imported machines.

Can high-precision cutting for stainless steel,carbon steel,galvanized sheet, silicon steel sheets, silicon steel sheets, titanium alloys, copper,brass, aluminum, ceramics, etc.\

Specification:

Model | YS-GW 300 | YS-GW 100W |

Laser power | 50W/100W/200W | 50W/100W/200W |

Wavelength | 1070nm | |

Beam quality | M²<1.1 | |

Working area | 600mm*600mm | 650mm*650mm |

Clamping size | 650mm*720mm | 650mm*720mm |

Cutting thickness | 0.3mm | 1.0mm |

Cutting speed pad/h | About 19200 | About 24000 |

Overall dimension | 1640mm*1380mm*1500mm | |

Weight | About 2200Kg | |

Positioning accuracy | ±2μ | |

Repeated positioning accuracy | ±2μ | |

Supply voltage | 220V | |

Power consumption | <2KW | |

Upper computer | Adavantech | |

Operating software | SmartCut | |

Cut document | LMD,CNC,DXF | |

Auxiliary cutting gas | Oxygen8-10Kg,Compressed air16Kg | |

Main material | savageness granite | |

Note:The above model laser power can be ordered according to customer needs.

Features:

1.It use iron core linear motor and double driver structure, large thrust, maximum acceleration can reach 2.0G, ensuring precise movement of machine under high speed.

2.Imported IPG fiber laser, stable output power, long life, maintenance-free, smooth hole processing, and ensure the stability of the processing process.

3.Using imported drives from the US, high-end adjustment and tuning algorithms greatly improve cutting performance and ensure machining accuracy

4.The whole machine uses natural marble as the base structure, which is safe and stable.

5.Equipped with a high-precision grating full-closed loop system for real-time feedback to reduce repetitive positioning errors.

6.Low energy consumption, the power consumption of the whole machine is about 2.5KW/h.