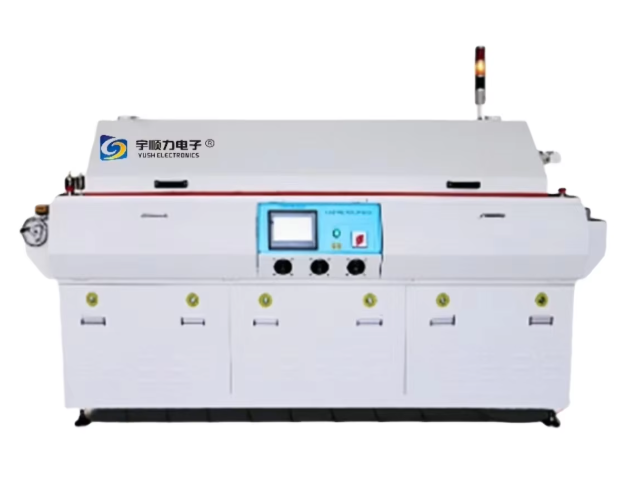

Introduce of Reflow Oven

Reflow oven is a machine mainly used to reflow soldering-mounted electronic components to printed circuit boards.

1.Control System

Computer or Instrument control, make sure machine working steadily.

2. Hot Air Heating System

Both top and bottom zones hot air heating, good heater compensatory,High thermal efficiency, energy saving, speedy heating,

suitable for soldering components like BGA,CSP etc.Special forced hot air circulation structure makes PCB and components

heat evenly, Temperature Accuracy ± 1.5 °C, room temperature settling time less than 20 minutes.

3.Cooling System

Independent cooling area ensures the low temperature when PCB comes out.

4.Transmission system

Use imported motors, speed adjuster, smoothly running, adjustable speed at 0-2000mm/min.

Specification of Reflow Oven

| Model | 622 | 733 |

| Dimension (L*W*H)mm | 5400*1400*1500 | 6250*1400*1500 |

| Machine Weight | Approx. 2200KG | Approx. 2400KG |

| Quantity of preheating zones | Up6/Bottom6 | Up7/Bottom7 |

| Length of preheating zones | 3030mm | 3730mm |

| Quantity of cooling zones | 2 | 3 |

| Control System | PLC+Computer | PLC+Computer |

| Transmission Agent | Chain + Mesh | Chain + Mesh |

| Width,sigle conveyor/without CBS | Standard:50mm-460mm, Option:50-686mm other Width on request | |

| Operating capacity | 10kw | 12kw |

| Conveyor Height | 900+/-30mm | 900+/-30mm |