High Quality Single-head online three-stage selective wave soldering For SMT prodcution Line

Machine specs

specifications | Parameter |

Overall Dimensions | 2850L*1650W*1850H (mm) |

Machine frame | Steel structure+baking paint |

Operating height | 900±30mm |

machine appearance | closed - type |

PCB board transportation method | Spray preheating guide rail chain transportation, welding roller transportation |

Programming methods of programs | Picture programming, Gerber document, visual teaching programming, etc. |

Welding real-time monitoring | standard configuration |

Weight | Approx.1500KG |

Power supply | 380V Three-phase five-wire system, 380V |

Total power | 30KW |

Operating mode | PCB board guide transportation, XYZ axis movement of solder pot, XYZ axis movement of flux spray valve. |

PCB parameter | |

PCB size | Min:30(L)*30(W); Max:500(L)*500(W)(mm) |

guide rail | Thirty to six hundred millimeters |

Guideway width adjustment method | Electric width adjustment |

Top component height | Max120mm |

Bottom component height | Max30mm |

PCB Weight | Max20Kg |

PCB Process Edge | >3mm |

Selective spray system | |

Spray movement mode | The spray valve moves on the XY axis. |

Mobile control mode | Servo motor + lead screw guide rail |

Spray flux volume | one liter |

Spray flux add mode | Manual |

Spray nozzle type | Spot fire valve |

Nozzle diameter | 0.13mm |

Spray cycle time | 1 Sec/soldered dot(The minimum spray time can be set to 0.1 seconds) |

Spray movement precision | ±0.1mm |

spray moving speed | Adjustable from 0 to 500 mm |

Spray flow control | pulse controller |

Preheating system | |

Preheating method | Heating from top and bottom |

Heating form | Upper infrared heating, lower infrared spotlight heating |

temperature control | Hot air setting temperature control, infrared heating rate ratio and time |

Temperature control accuracy | ±2 |

Selective Soldering System | |

Welding movement mode | The tin furnace moves along the XYZ axes |

Movement mode | Servo motor + linear rail |

Preheating compensation on the top of the solder pot | Hot air heating |

Solder feeding mode | Manual |

Number of soldering iron tips | one |

Solder capacity | 15KG |

Solder melting time | 45min |

Solder power | 1.2KW |

Solder nozzle size | Standard with 5 solder tips (3-64-8 6-10 8-12 10-14) |

Solder cycle time | 1~5Sec/ soldered dot |

Temperature control mode | PID+SSR |

Temperature setting range | Max350OC |

Temperature accuracy | ±2OC |

Waver height | Max 0-8mm |

Welding precision | ±0.1mm |

Solder dross | 0.2Kg/8H(Not N2 protection);0.01Kg/8H( N2 protection) |

N2 protection system | |

N2 protection mode | Nozzle and solder pot |

N2 consumption |

1.5M3/h(Nitrogen concentration>99.999%) |

N2 flow control | Glass rotor flowmeter |

Exhaust system | |

Top cover exhaust |

Customer supply |

Exhaust quantity | 2个 2PCS |

Exhaust vent diameter | 150mm |

Exhaust volume | About 15m³/h(Provided by the customer with an external exhaust channel) |

Control system | |

Control mode | PC+ motion control card |

PCB Process parameter | Setting, save , open in the PC screen |

Other | PCB counting, message, alarm can be read in the PC |

Common Wear & Tear Parts | |

Welding nozzle, nozzle cleaning fluid, high-temperature bearing | |

Machine key para

name | brand | brand belong |

Controlling | ||

industrial computer | Evoc | China |

monitor | Philips | ned |

Controller | positive motion | China |

SSR | Jiale | Switzerland |

box relay | Omron | Japan |

switch | Mingwei | chinese taiwan |

contactor | CHNT | China |

AC contactor | Schneider Electric | France |

sensor | Omron | Japan |

Motion parts |

| |

Servo motor | Panasonic | Japan |

servo driver | Panasonic | Japan |

ball screw | SHANGYIN | Taiwan |

linear guild | SHANG YIN | Taiwan |

Pneumatic |

|

|

Pressure sensor | AirTAC | chinese taiwan |

Air cylinder | AirTAC | chinese taiwan |

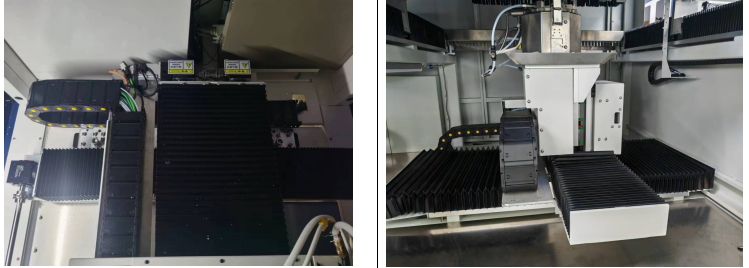

Panasonic servo motor & driver provide stable driving power, with screw pole & linear guild rail for guidance. Precious position, less noise, stable movement.

With dust proof plate above motion table, so to avoid flux or solder drop to damage ball screw.