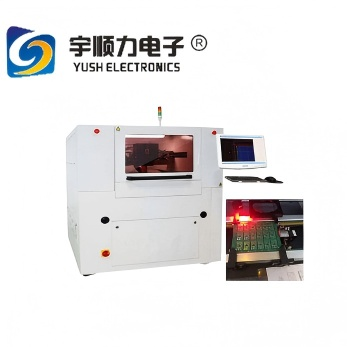

High Quality PCB Laser Cutting Machine YSV-7A For SMT Production Line

Description

Basic specifications and technical parameters | |

Specification/model | YSV-7A |

Laser head | SP (USA) |

laser type | UV |

Laser wavelength | 355nm light wave UV laser |

Max power | 10W /15w/17W |

Repetition frequency | 1-250kHz |

Worktable location precision | ±0.003mm |

Worktable repetition precision | ±0.002mm |

table reachition range | 500mm*500mm |

CCD location precision | 0.005mm |

Max working range | 460mm*460mm (Larger area 620*620mm can be customized) |

Beam spot size | 0.015mm ± 0.003mm |

Dimension(L*W*H) | 1300mmX1150mmX1455mm |

Weight(kg) | 1500KG |

Basic specifications and technical parameters | |

Laser machine supply power | AC220V / 3KW |

Material thickness | ≤ 1.0 mm |

Machine accuracy | ± 20 μm |

Platform positioning accuracy | ± 2 μm |

Platform repeatability | ±2 μm |

Focus spot diameter | 20 ±5μm |

temperature / humidity | 20 / <60% |

Machine main body marble | Galvanometer system CTI US original import |

Motion System Full Closed Loop AC Linear Motor System | Motion Control System PMAC (Delta Tau) |

Necessary hardware and software | Includes PC and CAM software |

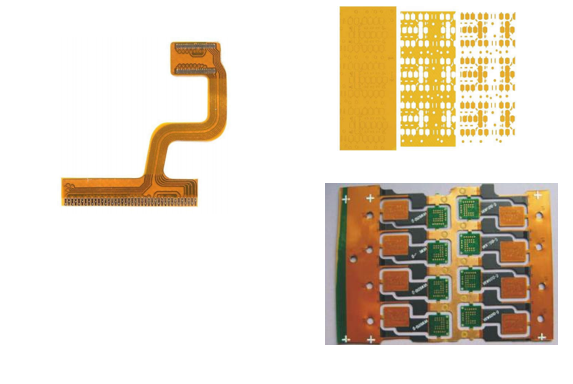

Efficient, fast FPC / PCB cutting, drilling and covering the window, fingerprint identification chip cutting, TF memory card sub-board, mobile phone camera module cutting applications.

Block, delimit, specify block or select area cut and form directly, cut edge neat rounded, smooth without burr, no overflow glue. Products can be

arranged in a matrix for multiple automatic positioning cutting, especially for fine, difficult, complex patterns such as the appearance of cutting .High- precision CCD automatic positioning, focusing, so that positioning fast and accurate, time-saving, high efficiency, fast delivery.

High-performance laser: the use of international brands of solid-state UV lasers, with a good beam quality, focusing spot is small, uniform power distribution, thermal effect is small, slit width is small, high cutting quality is the perfect cutting quality assurance.

Fast and high precision: High precision, low drift galvanometer with fast coreless linear motor system platform combination, fast cutting while maintaining the high accuracy of the order of microns.

Fully automatic positioning: the use of high-precision CCD automatic positioning, high precision, without human intervention, simple operation, to achieve the same type of one-click mode, greatly improving production efficiency.

Exhaust gas treatment system: suction system can cut all the exhaust gas to eliminate, to avoid the harm to the operator and the pollution of the environment.

High degree of automation: galvanometer automatic correction, automatic focus, full automation, the use of laser displacement sensor automatically adjust the focus to the height of the table to achieve fast alignment, time-saving peace of mind.

Easy to learn software: independent research and development based on the Windows system control software, easy to operate the Chinese interface, friendly and beautiful, powerful and diverse, easy to operate.

FPC UV laser cutting effect diagram