Welcome to the official website YUSH Electronic Technology Co.,Ltd

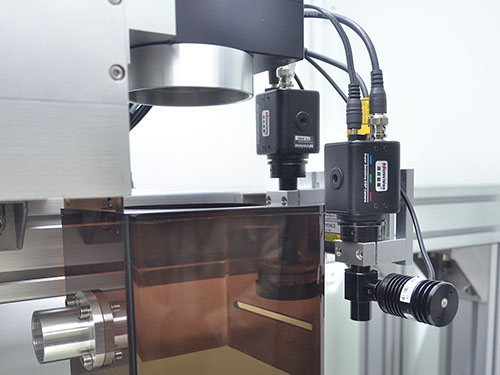

| YSATM-4C FPC Flexible PCB Laser Cutting Machine Laser Machine Yu Shun Technology brand is a positive instrument brands. Yu Shun FPC ultraviolet laser cutting machine, FPC laser cutting machine is mainly used CVL, FPC, RF, and thin plywood cut to shape. Technology has been committed to being the PCB industry equipment R & D and production, the company The FPC laser cutting machines, by the majority of customers. FPC UV laser cutting machine, FPC laser cutting machine use: Available for flexible circuit boards and organic coating for precision cutting without mold or protective plate fixation. By using a laser source of high energy and precise control of the laser beam can effectively improve the processing speed and to obtain a precise machining result. FPC ultraviolet laser cutting machine, FPC laser cutting machine characterized by: 1, with control software with independent intellectual property rights, user-friendly interface, complete functions, simple operation; 2, can process any graphics, cutting different thicknesses and different materials can be processed and the synchronization is complete hierarchical; optical system design optimization to ensure high beam quality, reduce the focused spot size, to ensure precision; 3, using high-performance UV laser with wave length, high beam quality, higher peak power characteristics. Due to ultraviolet light through decomposition, vaporization rather than melting materials processing to achieve, so almost no post-processing glitches, small thermal effect, no points Layer, the effect of cutting precision, smooth, steep sidewalls. 4, using vacuum fixed sample, no mold protection plate is fixed, convenient, improve processing efficiency. 5, can cut a variety of substrate materials, such as: silicon, ceramic, glass and the like. 6, automatic correction, automatic positioning function, multi-plate cutting, automatic thickness measurement and compensation, motor Bank and compensation, working better uniformity and small machining depth fluctuations, higher processing efficiency of complex graphics. FPC UV laser cutting machine, FPC laser cutting machine Technical parameters: Solid-state UV laser source laser wavelength: 355nm Laser power: 10W Maximum processing format: 610mm X 500mm (24 "X 18") or 610X500mm XY platform maximum operating speed: 50m / min Positioning accuracy: ± 3um Repeatability: ± 1um System precision: ± 20um Galvanometer scanning range: 50mm X 50mm Cutting thickness: <1mm Power and Power: AC220V 50Hz / 2.2KW; three-phase 380V 50Hz / 5.5KW Welcome home Requirements: 516m3 / h Dimensions: 1818mm X 2317mm X 1550mm Weight: 3500Kg Ambient temperature: 20 ℃ ± 2 ℃ Humidity: <60% RH non-condensing Ground Amplitude: <5um Vibration acceleration: <0.05g Ground pressure: 2200kgf / m2 Industry-specific control equipment, electric clothes formulated flexible processing software dedicated motion control card and IPC control mode With 17 monitors, hard drives over 300G standard G code, Gerber data, CAD YSATM-4C FPC Flexible PCB Laser Cutting Machine Laser Machine Yu Shun Technology brand is a positive instrument brands. Yu Shun FPC ultraviolet laser cutting machine, FPC laser cutting machine is mainly used CVL, FPC, RF, and thin plywood cut to shape. Technology has been committed to being the PCB industry equipment R & D and production, the company The FPC laser cutting machines, by the majority of customers. FPC UV laser cutting machine, FPC laser cutting machine use: Available for flexible circuit boards and organic coating for precision cutting without mold or protective plate fixation. By using a laser source of high energy and precise control of the laser beam can effectively improve the processing speed and to obtain a precise machining result. FPC ultraviolet laser cutting machine, FPC laser cutting machine characterized by: 1, with control software with independent intellectual property rights, user-friendly interface, complete functions, simple operation; 2, can process any graphics, cutting different thicknesses and different materials can be processed and the synchronization is complete hierarchical; optical system design optimization to ensure high beam quality, reduce the focused spot size, to ensure precision; 3, using high-performance UV laser with wave length, high beam quality, higher peak power characteristics. Due to ultraviolet light through decomposition, vaporization rather than melting materials processing to achieve, so almost no post-processing glitches, small thermal effect, no points Layer, the effect of cutting precision, smooth, steep sidewalls. 4, using vacuum fixed sample, no mold protection plate is fixed, convenient, improve processing efficiency. 5, can cut a variety of substrate materials, such as: silicon, ceramic, glass and the like. 6, automatic correction, automatic positioning function, multi-plate cutting, automatic thickness measurement and compensation, motor Bank and compensation, working better uniformity and small machining depth fluctuations, higher processing efficiency of complex graphics. FPC UV laser cutting machine, FPC laser cutting machine Technical parameters: Solid-state UV laser source laser wavelength: 355nm Laser power: 10W Maximum processing format: 610mm X 500mm (24 "X 18") or 610X500mm XY platform maximum operating speed: 50m / min Positioning accuracy: ± 3um Repeatability: ± 1um System precision: ± 20um Galvanometer scanning range: 50mm X 50mm Cutting thickness: <1mm Power and Power: AC220V 50Hz / 2.2KW; three-phase 380V 50Hz / 5.5KW Welcome home Requirements: 516m3 / h Dimensions: 1818mm X 2317mm X 1550mm Weight: 3500Kg Ambient temperature: 20 ℃ ± 2 ℃ Humidity: <60% RH non-condensing Ground Amplitude: <5um Vibration acceleration: <0.05g Ground pressure: 2200kgf / m2 Industry-specific control equipment, electric clothes formulated flexible processing software dedicated motion control card and IPC control mode With 17 monitors, hard drives over 300G standard G code, Gerber data, CAD |