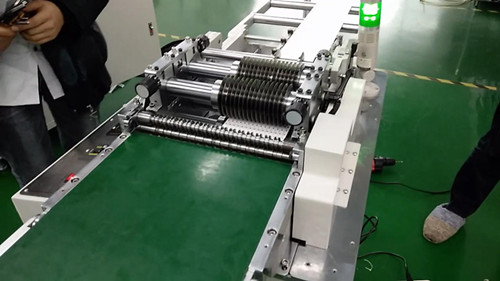

1. The shaft of the knives( top and bottom) is design to be an an integral whole, it is convenient to install, pick and place.

2. This machine adopts computer screen control with a counting device which can be preset production. Gap of the

depanelizer pcb tool displayed by the display screen directly.

3. All the v-cut pcb board can be

depanelizer by this machine.

4. Using the machine to

depanelizer , reduce stress, prevent the solder joint cracking.

5. pcb board is

depanelizer by multiple cutters which can

depanelizer several board once.

6. The machine top

depanelizer pcb wheel can be slightly adjust:0-5mm.

7. The distance between the knives can be adjusted, and it is suitable to

depanelizer pcb single pcb board within width 15-20mm.

8. Blade is made of SKH51 high speed steel with long service life and wear resistance.

9.

depanelizer pcb speed can be set and conveniently adjusted by turn-knob.

10. Install conveyer belt, pcb board which is cut can be sent out directly, then docking with the next machine and reducing the times of artificial pick and place. This machine can cut LED panel, fiberboard, aluminum board (more than 400mm ) and special board.

11. With several knives, the machine operates simply and efficiently and is suitable for mass production.

depanelizer pcb brushing machine - YSVJ-650Specification

Power : 110V/220V AC 60HZ/50HZ

Size: L1300*W400*H1000mm

Weight : 150kgs

Process of

depanelizer pcb is unlimited

depanelizer pcb thickness: 0.8-3.0mm