Introduce Features::

1.High Quality PCBA Router Machine, On-line PCB Router, PCB depanelingrouter Machine, PCBA Separator, LED pcb Depaneling, For PCBA.

2.On-line PCBA Router is a High-Precision High-Speed Dual-Platform On-linePCBA Router, Which is Used in Smart Phones, Smart Wear, Smart Home, TabletComputers, Automotive Electronics, Medical Devices, Aerospace, Military AndOther Fields.

3.New CCDSystem,New Vision System Can Correspond To All Kinds of PCB Mark Point.WithVisual Counterpoint Correction Function.

4.The Sensor CanMonitor The Milling Cutter State in Real Time, and effectively prevent thecontinuous operation of the cutter.

5. Using GermanyKAVo 4033AC-ESD high speed spindle, cutting stress is greatly reduced,precision is high, inertia is small, and response is fast.

6.Ion air gunwill remove static electricity on PCB surface and prevent dust from adsorbingon PCB.

7.Automaticloadering - picking and placing – cutting – unloadering pcba,unloaderingsolution can be option.

8.Adopt CNCspecial controller,high stability and strong anti-interference.

9.The separatedvacuum dust collector adopts high efficiency motor with high suction and lownoise.

10.Realizeautomation, save manpower and improve quality.

11.Automaticstorage product information, automatic adjustment conveyor width, improve thespeed of line change.

12.Loaderingpcba the automatic splint function replaces the traditional cylinder and ismore accurate.

13.Dual workingplatform to improve cutting efficiency.

14.Pcba can becut and move at the same time to improve productivity efficiency.

15.Standard MESor ERP connection ports, real-time connection to the central database.

16.Bar codecamera is option, which can scan barcode automatically and upload.

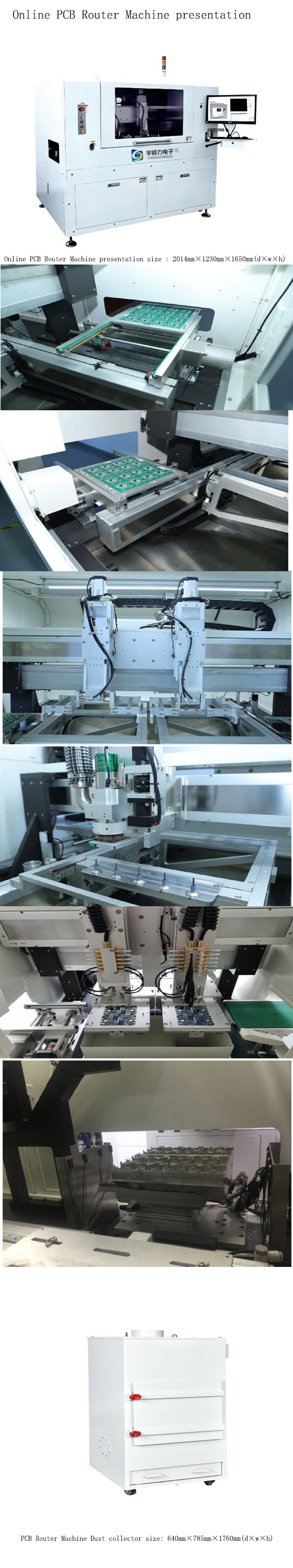

Specification:

Model | YASTM-4C |

Pcb Size(Special size optional) | 300*350mm |

xyz Drive Mode: | ac servo motor |

Number of motion axes: | 7 axes |

Program teaching method: | color CCD image intuitive teaching input |

Operation interface: | win7 window operation interface |

Upper vacuum power: | 2hp, lower dust collector power: 3hp (option 5hp) |

Cutting Spindle Syco Tec 4033 AC-ESD (Germany): | max80000rpm (automatic tool change) |

x-y ac servo speed: | 0-1000mm/sec |

z ac servo speed: | 0-800mm/sec |

x-y repeatability: | ±0.02mm |

Cutting accuracy: | ±0.08mm |

CCD camera calibration accuracy: | ±0.01mm |

Depaneling stress value: | below 300uε |

PCB thickness | 0.8~6.0mm |

PCB board cutting thickness: | 0.2mm-6.0mm |

Main engine and dust collector voltage: | 220v 1φ and 3φ |

Power consumption: | 3.5kva |

Static elimination gun | |

Vision system: | high-resolution digital camera |

Drive motor: | AC brushless servo motor |

Mechanical pick and place arm: | anti-static vacuum nozzle |

Feeding method: | rail conveying |

Discharge method: | belt conveying or carrier output or rail conveying |

Transfer method: | vacuum suction nozzle adsorption transfer |

Flow direction: | left → right |

Program backup: | usb interface |

Control method: | dedicated controller |

Dust collection cabinet size: | 640mm×785mm×1760mm(d×w×h) |

Dimension : | 2014mm×1230mm×1650mm(d×w×h) |

Host + dust collector weight: | 1000 kg |

Operation and Data Storage: | PC System |

Dust Collector | |

Dust Collection Method | Vacuum cleaning |

Air volume of vacuum cleaner | 12~20cm3/min |

Vacuum cleaner Dimension | 750*600*620mm |

Voltage of the Dust Collector | 380V,50/60HZ, 1.2k |

The structure of the vacuum suction cup to take the plate | |

Pick and place device | automatic loading and unloading (modular vacuum suction claw, vacuum device, can be independently controlled) |

Transmission structure | X2 axis moves Z2, Z3 axis sucks, AC servo motor control. |

Board taking speed | 0-1000mm/sec (can be set) |