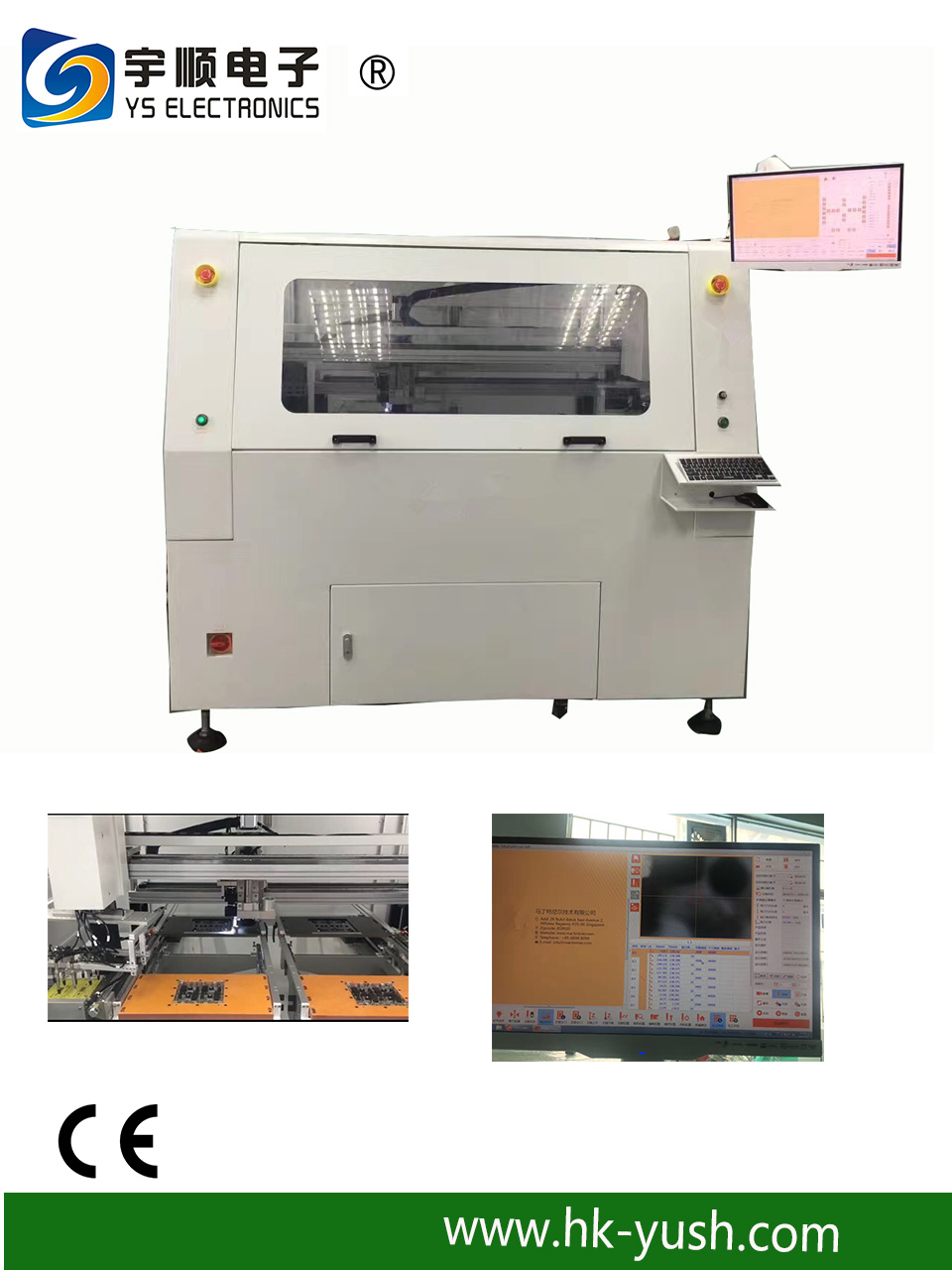

PCB Depaneling machine Inline -YSVC-650-In-line circuit board cutting machine

PCB Depaneling machine Inline -YSVC-650-is a user-friendly intelligent circuit board cutting machine, equipped with high-speed CCD vision alignment device, the use of YuShLi OR algorithm to ensure that the equipment in high speed and high precision operation. The cleanliness of PCBA is improved with a clean vacuum cleaner. Selection of NSK high-speed spindle, cutting stress is small, smooth side board. Especially for high capacity, high precision, high demand for customers.

PCB Depaneling machine Inline -YSVC-650-Technical Specifications:

Work: Online

Cutting function: straight line, arc, curve

Vision system: high-resolution digital camera

Drive motor: AC brushless servo motor

Number of motion axes: 7 axes

Mechanical take arm: anti-static vacuum nozzle special gripper

Working range: 250 × 350 mm

Work table: double table

Cutting speed: 0-100mm / s

Mechanical repeatability: ± 0.02 mm

Positioning accuracy: ± 0.02 mm

Cutting repeatability: ≦ 0.1 mm

Applicable PCB thickness: 0.3-2.0 mm

Milling cutter diameter: 0.5-4.0 mm

Spindle speed: Max 60,000 rpm

Operation interface: Windows 7

Voltage: AC380V, 50HZ

Dust collection: under the dust (standard) or dust on the dust

Air source: 0.5MPa

Machine size (mm): 1902W × 1550D × 1615H

Weight: 1300kg

Features:

1. Use the MARTIN OR algorithm

Automatically optimize the cutting path;

Servo error real - time tracking feedback

Camera fixed point, positioning axial position compensation.

2. CCD scanning function

Industry-leading PCBA full-board scanning, changing the traditional visual guidelines;

Shorten the programming time, the path real-time display, easy to modify simple.

3. Two-dimensional code automatically withdraws the program

Through the rule of a two-dimensional code can be directly transferred to the program, convenient, simple, no error;

Product switching intelligent.

4. Operation error, full monitoring

Cutting process, identification point error real - time recording

Motion axis error real - time recording;

The error value can be set according to the product needs.

5. Milling cutter intelligent mode:

According to PCB thickness adjustment knife depth, improve utilization, cost savings;

Define the standard for milling cutter according to product needs;

Replace the cutter, no need to redo or modify the program, click on the conversion can be achieved.

6. Transfer order mode to achieve automatic cutting

The cutting process is combined with the production model and quantity, according to the PMC plan;

To avoid the emergence of advanced production and production capacity is not clear;

To avoid modifications in the non-production process;

To achieve man-machine separation.

7. Industry 4.0 - MES system

Server data is automatically retrieved;

Uploading machine data and production data;

Real-time monitoring of equipment status.